CKD is focused on quality and sustainability. It's no wonder their automation products are ideal for operational efficiency.

CKD is a pioneer of automation technology and products that support a wide variety of industrial fields. CKD's emphasis on safety, quality, and sustainability efforts drives their manufacturing processes by developing original, earth-friendly products with their automation and flow control technologies.

elliTek's integration background and firsthand experience with CKD products create a unique partnership designed to empower our customers as they work to implement their ideas for driving efficiency in their environments.

Explore CKD's Solutions

With such an extensive product line, your choices may seem overwhelming. elliTek's engineers are here to help.

CKD's Electric Solutions:

CKD's Pneumatic Solutions:

-

Hanging

-

Fixed

What do elliTek's engineers like about CKD's products? Check out this episode of elliTek's podcast "Industrial Automation - It Doesn't Have To..."

CKD's Electric Solutions

Electric actuators are much different from pneumatic actuators. Deciding which actuator is best for your application depends on the power and speed you need. Pneumatic actuators are more powerful and faster than electric linear actuators. They can also be less expensive in the short term which makes them a popular choice.

On the other hand, pneumatic actuators rely on rudimentary devices like rubber cushions or shock absorbers, pressure regulators, and flow-restricting fittings at the port to control their motion. In addition, pneumatic actuators are powered by compressed air which can be wasteful and drive up energy costs. Listen to elliTek's podcast "Industrial Automation - It Doesn't Have To... Be Wasteful" to learn more about what we call Anti-Air.

Electric actuators have a lot going for them. They use electricity to create and power motion. Most electric actuators have a ball or screw connected by a coupler to a power source. To create power, these actuators can use servo or stepper motors. Servos are more precise and can take faster speeds; however, this does come with a higher price tag. Steppers are less expensive and still quite accurate at lower speeds. Electric actuators are commonly used in precise, delicate applications since they are easy to control.

An electric actuator is easy to add to existing systems. They require fewer components and have lower operating costs.

CKD's EBR-M and EBR-G rod-style electric actuators with built-in guide type. Perfect for Assembly and Inspection applications.

Reduce the need for additional guides with CKD's compact EBR series electric actuators. Their structure can withstand offset work and still attain high rigidity.

For direct installation, there is no need to remove the cover which saves time.

CKD's EBR-M and EBR-G rod-style electric actuators with built-in guide type. Perfect for Assembly and Inspection applications.

CKD's EBR Series electric actuators have built-in outer rail type guides that reduce the need for additional guides. Its compact and highly rigid design saves space. Additionally, an absolute encoder without batteries can be installed in order to retain position information even during an emergency stop and origin return isn't required.

CKD's electric actuator line includes the following:

-

Slider - EBS-M/G Series

-

Rod with built-in Guide - EBR-M/G Series

-

Controller - ECR Series

-

Controller - ECG Series

CKD's EBS Series slider-type electric actuators are compact with high rigidity and designed with an outer rail-type guide. When a battery-free absolute encoder is installed, the position information is retained even after an emergency stop, and the need for origin return is eliminated.

In addition, CKD designed the EBS series for uncomplicated, easy maintenance thereby extending the life of the actuator if maintained on a regular basis. Batch lubrication is performed through the greasing port on the side of the main unit. The main unit can be installed from either the top or bottom for easier maintenance.

CKD's slider type electric actuators are an excellent choice for Assembly and Inspection applications.

By downsizing the actuator, CKD designed the EBS series slider type electric actuators to save space.

The cover on CKD's electric actuators does not have to be removed for a direct installation which significantly reduces installation time.

CKD's slider type electric actuators are an excellent choice for Assembly and Inspection applications.

CKD's rotary-type electric actuators offer a wide range of operations and are a good fit for Assembly, Handling, and Inspection applications.

CKD equipped their rotary-type electric actuators with a manual apparatus that can be operated without tools. Easy positioning can be achieved at startup or when held by the self-locking mechanism.

CKD designed the FGRC model so soft starts and stops are possible and no shock absorbers are needed to save space.

CKD's rotary-type electric actuators offer a wide range of operations and are a good fit for Assembly, Handling, and Inspection applications.

CKD's Rotary-Type electric actuators are ideal for Assembly, Handling, and Inspection applications. A variety of operations such as multipoint positioning of the table and reverse operation of the held workpiece are possible.

The features that set CKD apart from the rest include:

-

Reducing Adjustment Time of Equipment

-

Simple Layout Concept

-

Space Saving of Equipment

The FGRC model is just one of many. View the digital catalog to see the extensive line of CKD's rotary-type electric actuators.

The actuator you choose depends on the speed and power you need, as well as what you'll be using the actuator for. elliTek's engineers have the expertise and knowledge to help you choose the right actuator for your application.

CKD's Direct Drives

Direct Drive motors whether linear or rotary do not use gears, pulleys, belts, or other transmission components to drive a load or rotor. The load or rotor is connected directly to the motor. Because the mechanical components in Direct Drive motors are eliminated, the number of moving parts in the system is greatly reduced.

A common misperception is Direct Drives are expensive when compared to traditional motors. In a simple comparison that may be the case. However, the mechanical simplification of Direct Drives with the elimination of intermediate gears, couplings, and maintenance, exemplifies that Direct Drives can be the most cost-effective and high-performing solution for many applications.

The term "Direct Drive" is typically used when referring to brushless, permanent-magnet, synchronous motors that transfer their torque direct to the load or rotor.

Direct Drive motors require more energy to pick up speed which can be viewed as a disadvantage. Once they get going though, they can reach higher maximum speeds because they build and maintain that speed.

Other advantages of Direct Drive motors include increased accuracy due to precise control of position and speed, reliability, no backlash or wear, compact designs, low maintenance, and increased efficiency.

Direct Drive Motors offer increased accuracy, high speeds, low maintenance, increased efficiency, and reliability.

All actuators use absolute type position detectors. The driver and actuator can be used in combination. CKD's general purpose direct drive motors can be used in a variety of applications including assembly.

AX1000T is highly accurate with indexing accuracy of ±15 seconds. AX2000T is ideal for high speed operations. AX4000T is available in 8 models and is the standard flat series with large hollow bore.

Supports AXs startup adjustment through six actions: edit, display, parameter, action, copy and tuning. It support driver TS/TH and conventional models.

All actuators use absolute type position detectors. The driver and actuator can be used in combination. CKD's general purpose direct drive motors can be used in a variety of applications including assembly.

All CKD actuators are absolute types.

CKD's ABSODEX Direct Drive motors offer reliable motion control for a wide range of torque loads. The quick, high-accuracy positioning is easily operated by a compact driver and user-friendly software that's compatible with almost any PLC network.

CKD's ABSODEX Direct Drive motors can be used for any application.

-

AX1000T Series: High Accuracy. Ideal for Assembly & Inspection.

-

AX2000T Series: High-Speed operations.

-

AX4000T Series: Allowable load inertia and Variation. Excellent for Assembly, Conveyors, and Index tables.

-

AX6000M Series: Compact. Perfect for miniaturizing equipment.

-

AX7000X Series: High Precision. Suitable for precision alignment and positioning.

CKD offers a robust line of high-performing Direct Drive motors with the industry's highest resolution encoder and a wide range of torque loads. Which direct drive is best for your application? Ask an engineer!

CKD's Pneumatic Solutions

Pneumatic systems are typically powered by compressed air. Although elliTek devoted a podcast to Anti-Air, there are advantages of pneumatics. Safety hazards are significantly reduced since pneumatic systems run on air. The initial cost of a pneumatic system is lower because pneumatic devices are made from relatively affordable materials. Compared to hydraulics, pneumatic systems are cleaner since the system is powered by air. Even though the system requires oil to work properly, maintenance is reduced as a result of less plumbing than hydraulic systems.

Fieldbus Manifolds

CKD's PLC Compatible Manifolds offer the power of decentralized communication with flexibility in control design. CKD's latest innovations in Fieldbus technology not only give you flexibility and control, but also considerable savings in labor. The wide range of open Fieldbus protocols that CKD supports includes EtherNet/IP, EtherCAT, CC-Link, and DeviceNet.

CKD's Fieldbus Manifolds are:

-

Excellent for Preventive Maintenance.

-

Provide a variety of IP address settings.

-

Offer a wide range of connection types.

CKD's PLC compatible block manifold consists of the MN3E series and MN4E series. These manifolds are high-performing and compact with a height of 39.5 mm.

Industries suitable for CKD's MN3E and MN4E include semiconductor manufacturing process (pre-process), components for chemical liquid supply facilities, components for chemical gas supply facilities, and N2 purging-related products.

Which Fieldbus manifold is best for your application? Talk to one of elliTek's engineers.

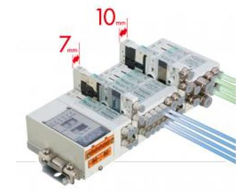

CKD's PLC-Compatible Block ManifoldCKD has two Fieldbus manifolds models: MN3E (3-port valve) and MN4E (4-port valve). |  Communication SupportThe wide range of open Fieldbus protocols that CKD supports includes EtherNet/IP, EtherCAT, CC-Link, and DeviceNet. |  Space SavingCKD's MN3/4E00 Series are extremely thin at 7mm. The MN3/4E 0 Series is just 10mm and provides exceptional responsiveness. |  CKD's Conservation EffortsCKD was a pioneer in reducing chemical substances affecting the environment. Option E (the energy saving type) reduces power consumption even further. |  Variety of Fitting Variations and electrical connectionsCKD offers inch-size compatible with push-in fitting. Serial transmission to various connectors and networks is available. |  Safety FeaturesAs a standard, CKD's MN3/4E Fieldbus manifolds have exhaust check valves, manual covers to prevent misoperation, and air supply filters to prevent foreign material from entering. |

|---|

Pneumatic Cylinders

CKD's Pneumatic Cylinders are an easy and economical way to automate and are suitable for a wide range of industries. To further their environmental initiatives, CKD incorporates "air pressure technology" to save energy. As a pioneer of pneumatic technology, CKD is continuously developing new products that meet the market's needs.

As an Engineering Elite Distributor, elliTek provides a level of service and support that empowers our customers. While you're researching your pneumatic cylinder options, keep in mind that elliTek's engineers are here to assist!

"CKD has exceptional products. We have CKD products that have been running for 20+ years!"

~Senior Maintenance Engineer

Pneumatic Chucks

A chuck is a specialized clamp that holds an object in a specific position. In a drill or mill, the chuck holds the rotating tool. In a lathe, the chuck holds the rotating part. Many chucks have jaws that hold the part or tool when tightened.

A three-way jaw-bearing chuck is also called a universal chuck because it holds round and hexagonal parts for quick and fairly accurate centering. Three-jaw chucks are typically used on indexing heads and lathe machines. The jaws in a three-way chuck are interconnected by a scroll gear and they move at the same time, self-centering.

On four-way chucks, the jaws move independently and an operators assistance is needed to center the workpiece.

CKD's 3-Way Jaw Bearing Chuck, Model CKG offers:

-

High precision with smooth operation due to a cross roller guide on the slide part.

-

Resistance to dust and debris.

-

Open / Close proximity switches.

Which chuck is best for your operation?

Collaborative Robot Grippers

End of arm tooling (EoAT) is an essential part of any robotic system. It's the piece that is normally attached to the end of a robotic arm and acts as the robot's "wrist." EoAT is what allows the robot to perform specific tasks. Learn more about EoAT.

CKD's pneumatic grippers for collaborative robots (cobots) are super-easy to install and replace without tools. The grippers highlighted in this section are customized for Universal Robots' cobots. CKD's UR-certified pneumatic grippers include UR-certified software that minimizes teaching time. For increased safety, these grippers are equipped with an edgeless resin cover and LED indicator light that is viewable from all angles. These grippers are ideal for Assembly, Handling, and Inspection Applications.

CKD has customized grippers for FANUC and Omron's cobots as well. If you're interested in learning about CKD's other grippers, let us know!

Lift Assist Devices

Tired of sore backs and slow production?

CKD's Lift Assist Devices are here to supercharge your production line! ⚡️

Here's how they'll win you over:

-

Faster cycles, fewer workers: Get more done in less time with optimized lifting and reduced manpower. ⏱️

-

Strong backs, happy workers: Say goodbye to operator strain and hello to a safer, more comfortable workplace.

-

Bend it like Beckham (or your machine): Choose from automatic or manual balancing, and tackle both vertical and radial lifting tasks. ⬆️ ⬇️ ➡️

Ready to revolutionize your production? Contact elliTek today!